Our bucket elevator line centers around models that range in capacity from 300 to 25,000 cu ft./hour, typically single-trunk design, with heights of approximately 100 feet or less. We have designed and manufactured elevators to much greater heights and capacities and do so on a case by case basis. SCC elevators, whether centrifugal or continuous design, are built with meticulous attention to detail and your job-specific requirements. SCC’s Huck® bolted casing sections allow for easy assembly, consistent structural connection, and time saving erection. The result is a superior elevator housing. SCC’s engineering expertise and design capabilities enable us to manufacture Super Capacity and Mill Duty Elevators. Work with your regional SCC Representative or local Distributor to review and communicate your specific details to our industry leading team of application engineers.

Centrifugal Bucket Elevators

Available in both Belt and Chain designs, the Centrifugal Bucket Elevator provides an economical, efficient and reliable means of elevating a wide variety of dry, free-flowing materials. Bucket spacing is further apart and the buckets travel at higher speeds than the Continuous-style.

Continuous Bucket Elevators

Available in both Belt and Chain designs, the Continuous Bucket Elevator has bucket spacing much closer than the Centrifugal design. This model is recommended for handling sluggish, aerated and friable material and operates at slower speeds than the Centrifugal-style.

Not Just Another Company

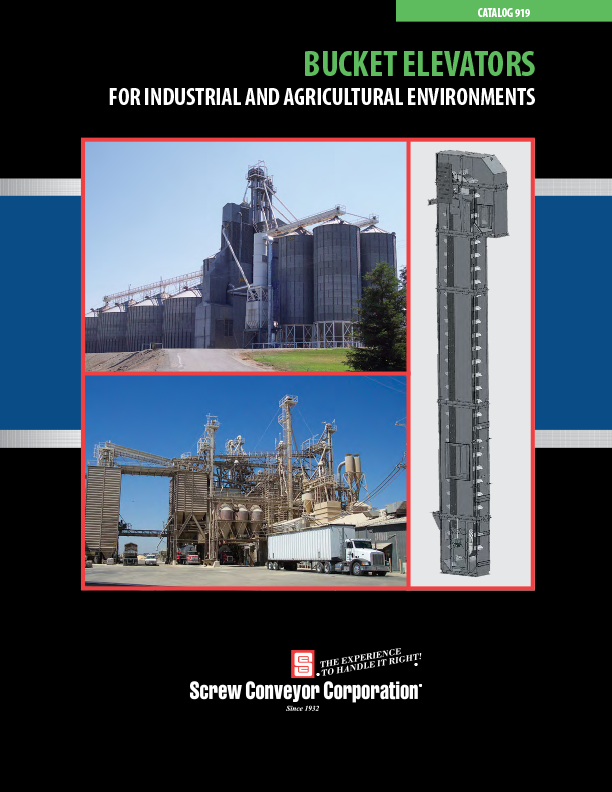

You simply can’t go wrong with Screw Conveyor Corporation. We’ve successfully provided served the bulk material handling solutions for over 85 years. We have three locations throughout the United States that serve the North American market. Our fourth location, Screw Conveyor de Mexico, serves Mexico, Central America and South America. We engineer and manufacture basic and complex conveyance systems. Rest assured that we have a solution for you.

Centrifugal & Continuous Bucket Elevators

| Typical Discharge Heights | 10 – 100 ft. |

| Typical Capacities | 300 – 12,000 cu ft./hour (industrial environments) |

| 1,000 – 25,000 cu ft./hour (agricultural environments) |

Reference Chart for Grain Handling Solutions

| Equipment | Capacity | Incline | Product Degradation | Application | Particle Size | Length/Height |

|---|---|---|---|---|---|---|

| Screw Conveyors | Up to 14,000 bushels/hour | 0 – 45° | High | Non-abrasive to abrasive | Small to medium | 3 – 150 ft. |

| Screw Lifts | Up to 2,400 bushels/hour | Vertical | High | Non-abrasive to low abrasive | Small to medium | 9 – 50 ft. |

| Round Bottom Drag Conveyors | Up to 20,000 bushels/hour | 0 – 30° | Low | Non-abrasive to medium abrasive | Small to medium | 10 – 150 ft. |

| Flat Enmasse Drag Conveyors | Up to 33,600 bushels/hour | 0 – 5° | Low | Non-abrasive to medium abrasive | Small to medium | 10 – 150 ft. |

| Compartment Drag Conveyors | Up to 20,000 bushels/hour | 0 – 75° | Low to medium | Non-abrasive to medium abrasive | Small to medium | 10 – 150 ft. |

| Bucket Elevators (Legs) | Up to 20,000 bushels/hour | Vertical | Low to high | Non-abrasive to highly abrasive | Small to large | 12 – 120 ft. |